Take Advantage of Ideal Diodes with Integrated MOSFETs

Contributed By DigiKey's North American Editors

2025-02-25

Ideal diode technology provides numerous benefits to electronic applications, including reduced voltage drops, enhanced system control, and robust protection features. Product designers can leverage the full potential of these advanced solutions to create more efficient, compact, and robust products. But selecting the right ideal diode for an application requires finding a balance of multiple factors, including electrical performance, thermal considerations, reliability, cost, and compliance.

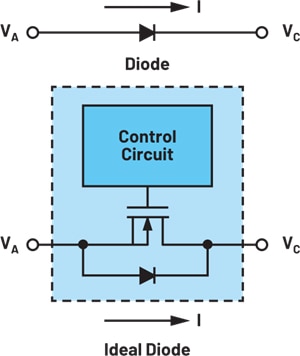

Traditional diodes exhibit a voltage drop ranging from 0.6 V to 0.7 V, with Schottky diodes dropping around 0.3 V. In high-current applications, those drops can lead to significant power loss. An ideal diode (Figure 1) uses a low on-resistance power switch, commonly a MOSFET, to mimic the unidirectional current flow behavior of a diode, but without the lossy diode voltage drop penalty.

Figure 1: This diagram illustrates the differences between a diode (upper) and ideal diode circuitry. (Image source: Analog Devices, Inc.)

Figure 1: This diagram illustrates the differences between a diode (upper) and ideal diode circuitry. (Image source: Analog Devices, Inc.)

A 10 mΩ MOSFET at a 1 A load, for example, has only a 10 mV drop compared to the typical 600 mV drop across a standard diode. This reduction in voltage drop also translates to significantly lower power dissipation. A 1 A load across a 10 mΩ MOSFET dissipates 10 mW, compared to the 600 mW dissipated by a regular diode.

With an additional back-to-back MOSFET and control circuitry, an integrated ideal diode solution can offer more advanced functions, including priority source selection, current limiting, and inrush limiting, adding a layer of sophistication to power management. Traditionally this required different controllers, making it complex and cumbersome to realize full system protection, but adding back-to-back MOSFETs to an ideal diode solution (Figure 2) provides total system control by enabling the turning on/off of one or both MOSFETs, or by limiting the current.

Figure 2: Diagram of an ideal diode solution utilizing back-to-back MOSFETs for advanced functionality and control. (Image source: Analog Devices, Inc.)

Figure 2: Diagram of an ideal diode solution utilizing back-to-back MOSFETs for advanced functionality and control. (Image source: Analog Devices, Inc.)

Integrated solutions deliver robust protection against common system faults, thereby reducing system downtime. Features like adjustable undervoltage lockout (UVLO) and overvoltage lockout (OVLO) thresholds, programmable current limits, and thermal shutdown protection ensure that systems remain operational even under adverse conditions. Integrated solutions can also help minimize the number of required components and board space.

Replacing traditional Schottky diodes with a MOSFET-integrated solution significantly reduces power dissipation, making it ideal for industrial power supplies, battery-powered systems, and redundant power OR-ing in telecom and data center applications. It can also ensure reverse input protection, preventing damage from accidental polarity reversals.

Challenges in selecting the ideal diode

Integrated ideal diode solutions are designed to ensure reliable and efficient operation in applications.

But designers trying to select an ideal diode face a range of challenges, including thermal management, current handling, voltage rating, integration complexity, cost, and component availability:

- Although ideal diodes lower power dissipation, thermal management remains a crucial consideration. Designers must ensure the diode can handle the thermal load without compromising performance. Proper heat sinking and thermal design are essential to prevent overheating.

- The current handling capability of the diode must be able to manage the application's expected current loads without exceeding rated limits. This involves evaluating the diode's RDS(ON) and ensuring it remains within acceptable limits under maximum load conditions.

- The voltage rating of the diode must be sufficient to withstand the maximum voltage levels in the application. Designers need to consider both the forward voltage drop and the reverse voltage rating to ensure reliable operation.

- While integrated solutions offer numerous benefits, they can also introduce complexity in the design process. Designers must ensure that all integrated features, such as UVLO, OVLO, and current limits, are configured appropriately, which may require additional design and testing time.

- Designers must weigh the benefits of integration against the added cost and determine if the added functionality justifies the expense.

- Designers must ensure that the selected diode is readily available and that there are no supply chain constraints that could impact production schedules.

Taking advantage of integrated solutions

Analog Devices, Inc. (ADI), a leader in power management solutions, offers a portfolio of ideal diode controllers which leverage MOSFET-based designs. The company's integrated solutions minimize power dissipation, improve thermal performance, and enhance system reliability, making them essential for industrial, automotive, telecom, and battery-powered applications.

Integrated solutions merge ideal diode functionality with additional system protection features such as overvoltage, undervoltage, hot swap, and eFuse protection, all within a single IC. Previously, these functions were dispersed across various controllers, complicating the realization of full system protection.

ADI’s ideal diode controllers, such as the MAX17614 (Figure 3), incorporate advanced reverse input protection, fast switchover capabilities, and high-voltage handling, enabling seamless power redundancy and improved energy efficiency. The MAX17614 is a highly integrated solution that provides a high-performance ideal diode with multiple other functions in a single integrated circuit to fully protect a power system.

The MAX17614 offers a reverse current-blocking protection of 140 ns, allowing for the use of smaller output hold-up capacitors in priority power source selector applications, which can enhance overall system efficiency. It combines ideal diode/priority power source selector functions with adjustable current limits, hot swap, eFuse, under-voltage (UV), and over-voltage (OV) protection.

Figure 3: ADI's MAX17614 ideal diode/power source selector device. (Image source: Analog Devices, Inc.)

Figure 3: ADI's MAX17614 ideal diode/power source selector device. (Image source: Analog Devices, Inc.)

Smaller solution size

Integrated ideal diode solutions minimize the number of required components and board space. For example, the MAX17614, with two integrated N-channel field-effect transistors (NFETs), enables up to a 40% reduction in solution size.

The integrated NFETs are connected in series with a low cumulative typical RDS(on) of 130 mΩ. They can be used to implement an ideal diode function that features reverse input voltage and reverse current protection with improved system efficiency. Input UV protection can be programmed between 4.5 V and 59 V, while OV protection can be independently programmed between 5.5 V and 60 V. Additionally, the device has an internal default UVLO rising threshold set at 4.2 V (typ).

The MAX17614's compactness is particularly beneficial in applications where space is at a premium. With a fast response time, high voltage capability, and minimal power loss, it has proven popular for use in solar energy systems, USB-C power delivery, industrial automation, and medical equipment, where efficient power management and reliability are critical.

Compared to discrete MOSFETs, integrated NFETs are optimized for thermal management, reducing the need for additional cooling components. They also enable fast switching between power sources in redundant power OR-ing applications employed for telecom and data center solutions. The NFETs also provide reverse input protection, preventing damage from incorrect voltage connections or back feeding.

With the integrated NFETs, the bill of materials (BOM) and PCB layout are simplified as designers don’t need to source and select external MOSFETs. They can take advantage of reduced component counts to create smaller, more compact designs.

ADI also offers the MAX17614EVKIT evaluation kit for designers to test and integrate the MAX17614 ideal diode controller into their power management solutions. The evaluation board provides a platform to assess the efficiency, switching behavior, and protection features of the integrated NFET-based ideal diode.

The EVKIT enables prototyping of efficient power path solutions for applications such as industrial power supplies, battery management systems, and redundant power OR-ing in telecom and server applications. The kit allows analysis of voltage and current behavior under different load conditions to help ensure optimal component selection and design layout, so designers can validate circuit performance before committing to full-scale PCB development.

Conclusion

Ideal diode technology offers high-efficiency, low-loss power path control for applications, including reduced power dissipation, minimized voltage drop, and improved thermal performance. By enhancing energy efficiency, reducing heat generation, and eliminating the need for bulky heat sinks, ideal diodes improve system reliability while simplifying PCB design. ADI’s MAX17614 and its companion evaluation board enable designers to create smaller, more efficient, and highly robust power solutions across a wide range of applications.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.